What is Electrolizing and Industrial Hard Chrome? |

Electrolizing is a proprietary thin dense hard chrome plating. The 70-72 Rc coating is applied to increase wear and corrosion resistance, while reducing friction, galling, seizing, and fretting to increase a products life span up to 1000 percent. The stringent control of thickness eliminates grinding requirements, with only light lapping or polishing to improve the finish if needed.

Industrial Hard Chrome is applied thicker usually two times the finished thickness to allow for grinding to size. Industrial hard chrome is also used to repair metal components.

Both coatings are applied directly to the base or substrate metal without an intermediate coating such as copper or nickel. This improves the coatings adhesion to your part and will not flake or peal off.

|

Quality Chrome Plating Specialists |

Internal and external surfaces on nearly all shapes and configurations can be uniformly coated. In general, the exceptions are slots or grooves less than .120 wide and a slot or grove having a depth greater than its width, which includes threads and splines. Holes or Bores less than .187 in diameter cannot be plated. |

Generally, parts should be less than 120 in length, 40 in diameter and not exceed 1500 pounds. Parts in excess of these limits should be discussed with us. |

Frequently Asked Questions |

Plating can be done on all ferrous and most non-ferrous metals; for example, tool steel, stainless steel, bronze, beryllium-copper, copper, and aluminum. The coating is not recommended for tin, magnesium, titanium, beryllium, columbium, and lead. |

What kinds of metals can be chrome plated? |

What are the plating size limitations? |

Are there Surface Geometry limitations? |

Electrolizing, Inc chrome plates per many specifications; for example, AMS 2460 (QQ-C-320), AMS 2406, AMS 2438, Mil-C-23422, DPS 9.71, DPS 9.84, EMS 250, PS13102, PWA 48, and BAC 5709 Type IV, and dozens of others. Please contact us with your process specification if not listed here.

|

What plating specifications are met by Electrolizing? |

1947 Hooper Ave. Los Angeles, CA 90011 Phone: 213-749-7876 Fax: 213-749-9880 |

Site Map Contact Web Master Company Policy Copyright © 2008 Electrolizing Inc. All Rights Reserved. Updated Sept 2010 |

How thin or how thick should the coating be? |

The coating thickness dimension and tolerance shall be specified on each part drawing. The practical coating range is from 0.000050(50 millionths) to 0.0006(6 ten-thousands) for the Electrolizing process. The tolerance is plus or minus ten percent of its true thickness.

For industrial Hard Chrome for grind, plating should be between 50% to 25% of desired thickness after grind. For example, .004 thickness is recommended to achieve a .002 after grind plating. Additionally, if a .005 thickness is desired then a thickness of .008 to .010 is recommended.

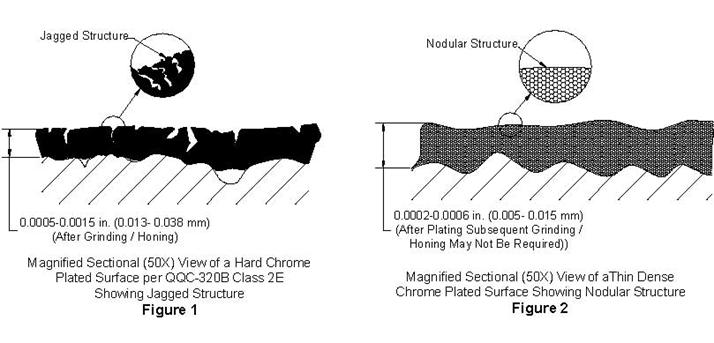

Shown below in figures 1 and 2 are typical magnified cross sections of Industrial hard chrome plating and thin dense hard chrome plating. |